Behind the Design

Drift, Mesa, Peak, and Valley

The designs by longtime creative partner Bernd Benninghoff, for Spinneybeck | FilzFelt, have explored a wide range of styles, manufacturing processes, and materials. His collections have incorporated a variety of techniques and materials, and have long set the standard for innovative surface design; this new series is no exception. One thing, however, connects all of his designs ― they consistently play with light and shadow, often protruding from the wall or incorporating v-grooves cut directly into the felt and acoustic substrate.

His latest collection of wall products is the natural next step in the evolution of his work. Years of experimenting with felt and continually prototyping and modifying existing designs have led to a series that builds on his previous work in a fascinating way.

Launched in 2020, Bernd designed Tac-Tile, a modular, tile-based acoustic wall system that creates a dramatic effect on a small scale. The individual tiles cleverly bend and fold to create points that pop off the wall. With Hive, Bernd first explored a range of patterns made possible by cutting shallow grooves through layers of felt and acoustic substrate. The collection features three patterns, all from a single hexagonal module with a v-groove design that rotates six different ways and fits together seamlessly in randomized installations. This past year, Bernd’s acoustic panels, Grain and Reeds, experimented with curved v-grooves that allow flowing lines that manipulate light and shadow, creating a subtle sense of movement.

And now, a collection of large-scale panels combines techniques and processes from each of these previous designs. This time, Bernd creates curved patterns that are v-cut and folded to develop panels with curved, undulating surfaces that, in true Bernd fashion, play with light and shadow in dramatic and eye-catching ways. We joined Bernd in his studio in Mainz, Germany, to chat about the evolution of this work, a recent trip to the South of Germany that led to the inspiration behind these newest folded designs, and his ongoing fascination with Wool Design Felt.

Tell us about the inspiration behind these designs!

The inspiration for the latest collection came from working and experimenting with the material itself. I have been working for years with digitally generated v-shaped incisions in fiber composite and felt - initially on the front of the material to create lines and graphics with depth (the Hive collection is a good example of this). For Grain and Reeds, cutting curved and radial lines into the felt has also been possible. While testing my prototypes for other designs, I discovered that the curved incisions could then be folded in really interesting ways. The flexibility of felt made a lot of new experimentation possible. The result was wonderfully soft and flowing shapes on the front, giving the material a strong spatial effect - I was instantly fascinated!

These have an almost origami feel to them. Did that art form have any impact on how you approached these designs?

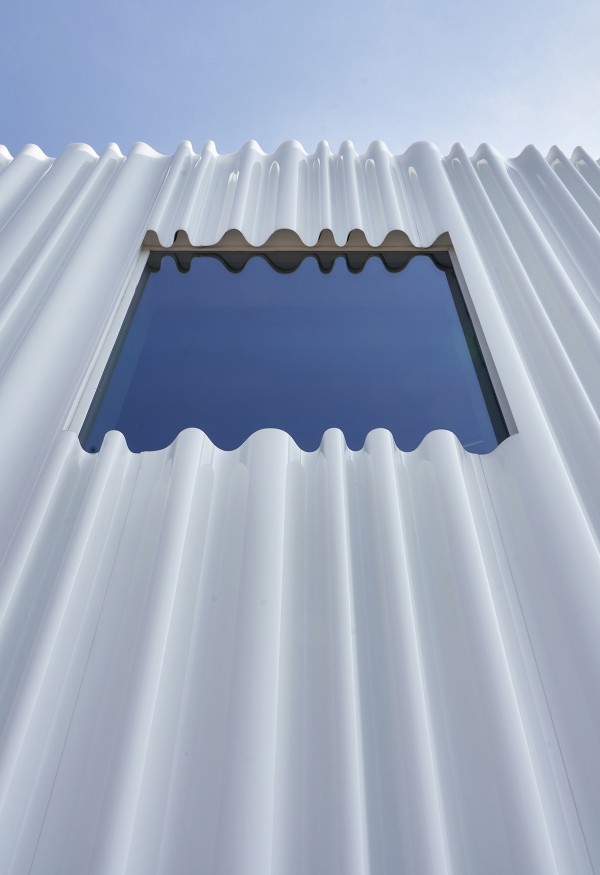

Even though origami inspires me, it did not play a decisive role in developing this collection. Interestingly, however, there was another Japanese inspiration. I recently visited a building designed by Japanese architecture firm Sanaa in southern Germany. I was fascinated by the architecture of the industrial structure that features an undulating facade of large acrylic glass modules that wrap around the entire building like a curtain. It gives the building an incredible lightness and elegance. The impact of these meter-high, curved modules immediately came to mind when I examined my own prototypes. The possibility of developing floor-to-ceiling, flowing modules from softly folded felt motivated me to build and test further prototypes.

"I recently visited a building designed by Japanese architecture firm Sanaa in southern Germany. I was fascinated by the architecture of the industrial structure that features an undulating facade of large acrylic glass modules that wrap around the entire building like a curtain. It gives the building an incredible lightness and elegance."

Can you walk us through the process of creating these designs? Can you tell us how you approached prototyping on an accessible scale, considering the final panels are about nine feet tall?

After experimenting with several small-format designs, I went straight to the computer and designed a series of large-format elements that can be extended endlessly, enabling large, expansive installations. I initially tested on a smaller scale with cardboard, but these experiments didn’t yield much insight since they didn’t account for the material properties of the final version. Cardboard and felt will, of course, produce very different outcomes, so I had to test with felt and a backing on a larger scale to get as close to what the final design would be.

The challenge was to develop a perfect template for each design to ensure alignment when panels are installed side-by-side. The prototyping process was tricky as the pattern results from a precise relationship between line and substructure and emerges only after modules are compressed. The first full-scale tests took several days of testing and optimizing the designs on a 1:1 scale, but the final results were instantly fascinating.

The first version of the large modules measured roughly four feet in width which made them extremely hard to handle and to manufacture on an industrial scale. Further development with the team at Filzfelt resulted in thinner modules that work way better than the original prototypes. They are easier to manufacture and much easier to ship and install - without losing their character.

What were the biggest challenges you faced developing this new collection?

The biggest challenge was experimenting with the material itself. Folding this material has different effects depending on the thickness. I needed to answer several questions during the prototyping process to get to the final, desired effect: How thick can the material be for the folding to work? How deep do the cuts need to be so there’s no tension? What is the ideal radius of the curves so the lines can still be folded? How can we design the lateral transitions to remain as invisible as possible when creating a multi-panel installation? Many prototypes were necessary - all on a 1:1 scale - to finally get a strong and convincing result.

This scale is a notable departure from your smaller, tile-based designs. Can you tell us about your approach to something considerably different?

With this collection, I wanted to design a wallcovering with long, three-dimensional lines that create soft, large-scale forms that flow in uninterrupted installations. I wanted the curves of the panels to give the impression of flowing curtains that create a continuous drape across the wall. The modules also have an extremely effective acoustic quality thanks to the three-dimensional surface and the substructure.

Are there any specific colors you feel emphasize the patterns?

For me, these folded designs work particularly well with all the colors in the Filzfelt collection. They emphasize the lines and patterns well, creating defined and eye-catching lines that make the space feel sophisticated and elegant. This effect is somewhat softened with the melange colors.

The positioning of the modules in relation to light is particularly important. When natural light falls from the side, it brings the modules to life and animates the panels throughout the day as the light shifts and changes. The shadows then reinforce the three-dimensional effect of the surface.

What makes felt a good fit for these new panels?

I can’t think of a better surface material for this collection. From a technical point of view, the felt acts as a hinge and makes folding possible. Its flexibility and stability are ideal for this particular application. At the same time, this wonderfully soft and supple material plays off the inspiration of a flowing curtain. Plus, it’s a very tactile material—soft and welcoming—inviting you to run your hands along the ripples and folds.

“I can’t think of a better surface material for this collection. From a technical point of view, the felt acts as a hinge and makes folding possible. Its flexibility and stability are ideal for this particular application. At the same time, this wonderfully soft and supple material fits in with the theme of a flowing curtain."

About Bernd Benninghoff

Bernd Benninghoff works as a furniture designer and interior architect based in Mainz, Germany. Since 2000, his design studio has developed serial furniture as well as room and exhibition concepts for international clients. For Bernd, objects and spatial context are interrelated. It is important for him to use authentic materials and appropriate manufacturing processes—in search of meaningful design solutions and room experiences with an independent character.